BUOYANCY PROTECTION AGAINST GROUNDWATER RISE, GWS

Buoyancy protection against groundwater rise, GWS (Ground-Water Safe) is carried out with 2 UWR Connect modules (towers) for every 75 m² of surface area.

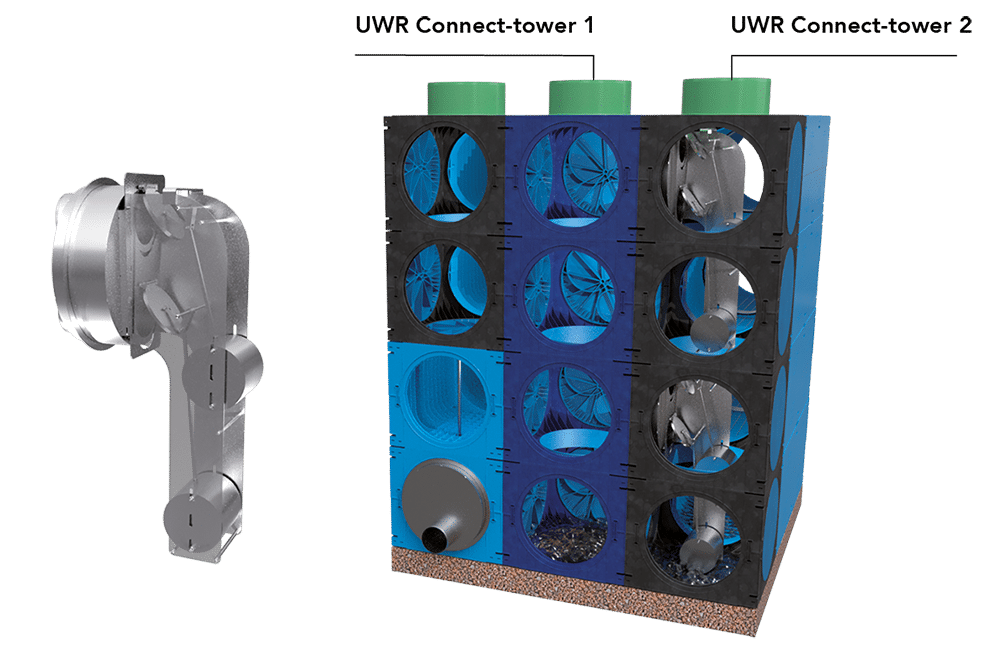

The UWR Connect towers (1) and (2) should be appropriately positioned in relation to the cleaning channels, preferably centered within the entire surface area of the basin.

UWR Connect tower 1 with GWS is closed on 3 sides with UWR Cover or UWR Connectring Closed against the other modules.

At the top, UWR CoverPipe 425 is installed for inspection, while the cover (UWR Cover) is omitted at the bottom.

UWR Connect tower (1) must have direct access to the subgrade, and the subgrade must be stable and follow the Road Directorate’s guidelines regarding load-bearing layers for road construction.

Under the basin, materials like geotextile can be laid out to direct water to UWR Connect tower 1.

The side facing the next UWR Connect tower (2) connects GWS with the two UWR Connect modules.

UWR Connect tower 2, in which GWS is installed, is connected to the rest of the basin system via UWR Connectrings and UWR Pipe modules. The purpose of having 2 closure units in GWS is to differentiate the water level in the basin and the groundwater level, allowing space for surface water in the basin. There will always be a 40 cm differential distance between the groundwater in tower 1 and tower 2.

When using buoyancy protection GWS, groundwater is utilized to keep the basin down, which means that extra volume capacity in the main basin must always be calculated.

Calculations for buoyancy protection with GWS must always be carried out by an Engineering Consultant.

Maintenance: The float assembly is removed from tower 2, and the rubber ring along with all moving parts are inspected.

The float assembly is then reinserted into the slot on the UWR Connect unit.

Tower 2 is accessed via UWR CoverPipe 425 for visual inspection.

It is recommended to inspect and service GWS at least once a year.